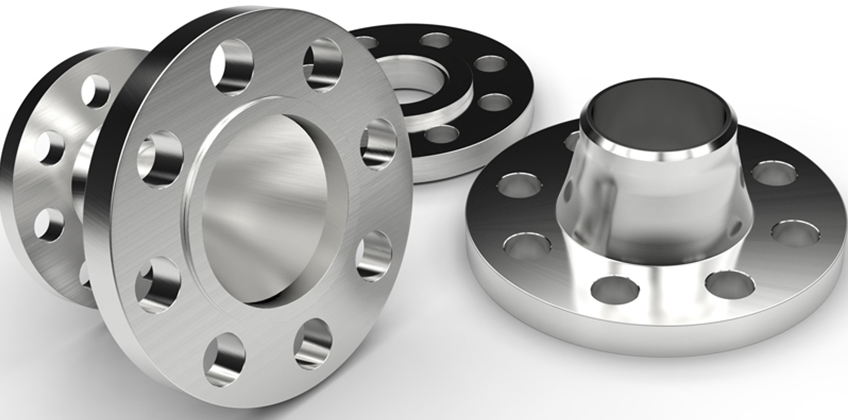

A piping structure used for connecting pumps, valves, and tubing with other parts of machinery is called flanges. Because of its various commendable properties and features, it is penetrating deep inside the steel industry and has eliminated the traditional process namely welding.

The popularity of flanges is growing in the steel industry, as it helps in making the washing, dismantling, alteration along with the flexibility in the maintenance process much easier which was absent in the case of welding. It also helps in reducing the problem of leakage owing to its great flanged joint structure which is framed by assembling three elements namely bolting, gaskets, and flanges with the pipefitter.

Mostly used Pipe Flanges in the steel industry

Some of the commonly used types of pipe flanges in the steel industry along with their uses are mentioned below:

● Threaded Flanges: are commonly known as screwed flanges that help in providing speedy and simple flange joint by using male thread inside the bore and are commonly used in utility services. This type of flange is cost-effective.

● Slip-on Flanges: This is the kind of flange that can be welded from outside and inside both ends through which the pipe can pass having the hole of the same diameter from outside. This is also a cost-efficient type suitable for different temperature applications and commonly used in large sizes.

● Lap Joint Flanges: consists of two elements majorly known as loose backing flange and stub backing flange. The former is generally made of carbon steel for cutting the cost and the latter is butt-welded majorly used for where dismantling is required frequently.

● Weld Neck Flanges is the most common type owing to their joint integrity feature which can easily be associated with high temperature and pressure applications.

● Reducing Flange: type can be used by replacing standard flange which further eliminates the standard reducer and generally contains smaller bore size diameter and can further allow in size change.

● Expander Flanges: alike weld neck flange that increases the size for the first or second larger size for the pipe. This can also be replaced as an alternative in the weld neck flange that helps in connecting compressors, valves, and pumps.

Conclusion: From all this information the importance of flanges is seen by reading the advantages of flanges in the steel industry as it is the latest technique. Contact us for the best flanges used in the steel industry.